COPPER BONDED RODS

CPRI tested and certified copper bonded rod earth electrodes are made of low-carbon steel of superior grade and quality, with a high tensile strength of at least 600N/mm2. 250 microns of copper is molecularly bonded to nickel sealed steel rods to avoid copper to steel merging. This provides ensured performance and double protection as required under UL 467 and IEEE spec which by our in-house testing making sure that our copper bonded rods are excellent in corrosive soil.

TEST CONDUCTED ON COPPER BONDED RODS AS REQUIRED UNDER UL 467 SPEC.

The following tests were satisfactorily conducted on copper bonded rods of sizes 17.2mm diameter 2.0 meters.

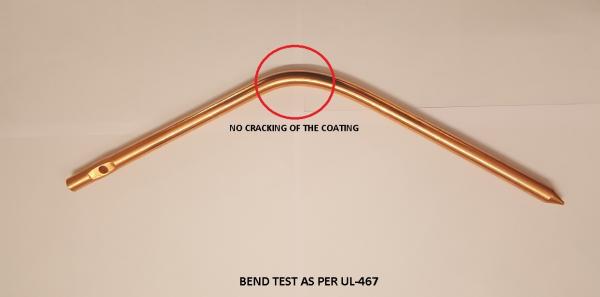

BENDING

TEST PROCEDURES: A length of the rod shall be rigidly held in a clamp or vice. Applied a force normal to the free end of the rods at a distance from the clamping device equal to 40 times the rod diameter. The application of the force shall be such that the rod is permanently bent through 0 30-degree angle.

RESULT: There was no cracking of the coating when subjected to the test described above. These different samples were subjected to the above test.

THICKNESS OF PROTECTIVE COATING

TEST PROCEDURES: The thickness of the protective coating shall be determined by a reliable magnetic coat tester, with the tester hold vertically on the specimen.

RESULT: The copper coating thickness was measured as 0.25mm or 250 microns at all the points of the rod. Three different samples were subjected to the above tests.

In addition to the above tests, CPRI, Bangalore have conducted short time withstand current tests on two different sizes of copper bonded rods. No cracking or breaking or melting of the rod was noticed after the test. The copper cladding was intact.

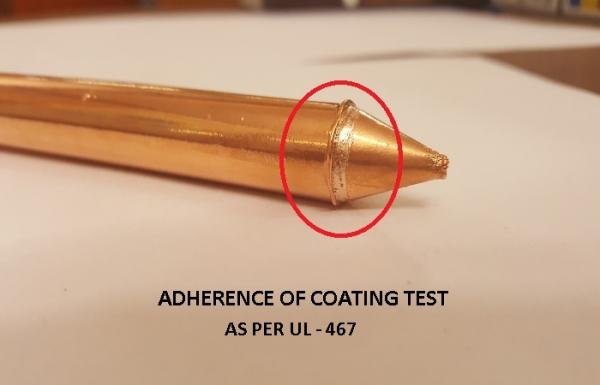

ADHERENCE OF COATING

TEST PROCEDURE: A 467mm (18) length of rod with one end cut to a 45 degree shall be driven between two steel clamping plates or the jaws of a vice set 1.02mm (0.04 inch) less than the diameter of the rod, so as to shear off sufficient metal to expose the bond between the coating and rod.

RESULT: There was no separation of the coating from the steel core when subjected to the test described above. Three different samples were subjected to the above test.